Frequently Asked Questions

How do I choose the right air compressor?

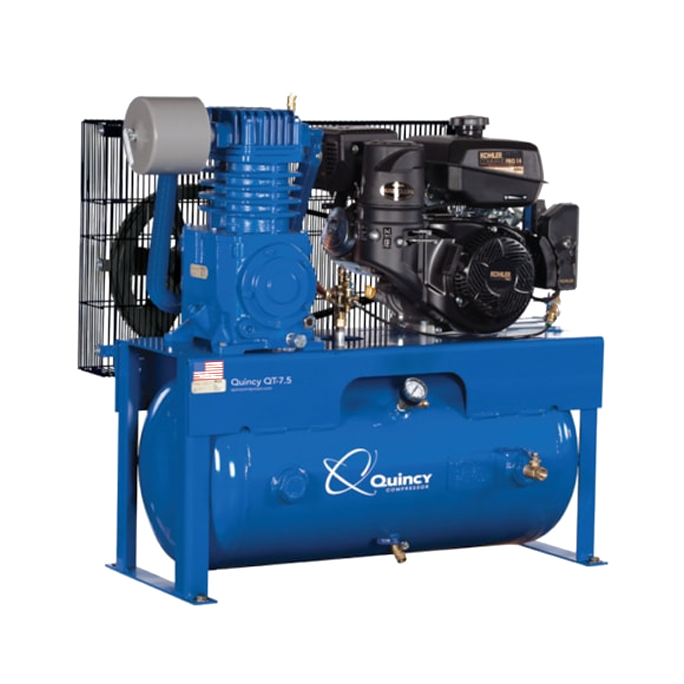

Start by identifying your current and future needs—what tools you’ll be running, the required pressure, and how often the compressor will be used. Add up the CFM requirements of your tools, then include about 25% extra to allow for leaks and future growth. Decide whether a portable gas-powered unit is best for job sites or if a stationary electric model suits your shop. Also consider tank orientation, single-stage vs. two-stage performance, and overall build quality. Higher-end compressors often last longer and may include features like automatic drains or overload protection. The right choice balances size, power, durability, and warranty for reliable long-term performance.

What is the difference between piston and rotary screw air compressors?

Piston (reciprocating) and rotary screw air compressors are two of the most widely used types, each offering distinct benefits depending on the application. Piston compressors are compact, affordable, and capable of producing high pressures, making them ideal for intermittent use and smaller tasks, though they generate more noise, vibration, and require frequent maintenance. In contrast, rotary screw compressors are designed for continuous operation, delivering steady, clean airflow with lower noise levels and longer service intervals, making them better suited for industrial or high-production environments. When choosing between the two, businesses should weigh factors such as size, application, duty cycle, airflow needs, noise tolerance, purchase price, energy efficiency, and maintenance requirements. For tailored guidance in selecting the right compressor, the experts at AirCompressors.com are available to provide professional support.

What is the difference between oil-flooded and oil-free?

Oil-flooded compressors are powerful, durable, and designed for heavy-duty, continuous use in industries like manufacturing and automotive. However, they require regular maintenance and carry a risk of air contamination. Oil-free compressors are lightweight, compact, and deliver clean, contaminant-free air, making them ideal for food, beverage, and pharmaceutical applications. They need less maintenance but typically have shorter lifespans, lower capacity, and can be noisier. Choosing between the two depends on your air quality requirements, duty cycle, maintenance resources, and portability needs.

Should I oversize my air compressor?

No. You should avoid oversizing your air compressor because it can lead to inefficiency, higher costs, and reduced lifespan. Compressors are built for a specific duty cycle, and when a unit delivers far more CFM than required, it tends to short cycle with starting and stopping too often. This prevents the machine from reaching optimal operating temperatures, which can cause moisture buildup, internal wear, and unnecessary stress on components. It also wastes energy, driving up operating expenses without adding value. The best approach is to size your compressor based on actual airflow (CFM) and pressure (PSI) needs to ensure consistent performance, energy efficiency, and long-term reliability.