When determining which air compressor is right for your operations, you’ll need to review your daily runtime, noise preferences, and tool demands to find which compressor fits your workload best. Rotary screw compressors offer quiet, consistent airflow for long work periods and are best for continuous, high-volume air needs. Piston compressors, also known as reciprocating air compressors, deliver strong, high-pressure output and are best for intermittent, high-pressure uses. Most buyers compare the two when they experience pressure dips, rising energy costs, or equipment noise and other factors that affect their output.

At AirCompressors.com, our team of experts can help you choose the best compressor for your needs based on your operational requirements. Shop our full line of air compressors today!

Piston Air Compressor vs. Rotary Screw: Quick Comparison

Before purchasing new equipment, it’s important to understand the differences between a piston air compressor and a rotary screw compressor in these key areas:

Performance and Duty Cycle

- Rotary screw compressor: Designed for longer runtimes with steady airflow

- Piston compressor: Produces strong pressure for shorter cycles

Noise Levels

- Rotary screw compressor: Often 65 to 75 dB

- Piston compressor: Commonly 80 to 90 dB or higher

Air Temperature and Moisture

- Rotary screw compressor: Cooler air discharge helps reduce moisture

- Piston compressor: Warmer air increases moisture risk

Energy Efficiency

- Rotary screw compressor: More efficient during heavy operation

- Piston compressor: Uses more energy during long periods of continuous use

Cost Considerations

- Rotary screw compressor: Higher initial cost

- Piston compressor: Lower upfront price

Best Fit

- Rotary screw compressor: Long shifts and consistent tool use

- Piston compressor: Smaller shops and intermittent work

These compressors are the most common industrial air compressor types utilized across various industries, so evaluating your operational needs and output will be critical in your purchase decision.

Costs and Maintenance

When it comes to buying new equipment, you must balance total cost of ownership, not simply purchase price. Costs vary based on workload, environment, and tool demand.

Here is a quick cost comparison for rotary screw and piston compressors:

Upfront Costs

- Rotary screw compressor: Higher initial cost

- Piston compressor: Lower initial cost

Operation Costs

- Rotary screw compressor: Saves energy during long shift

- Piston compressor: Uses more energy during extended operation

Service Needs

- Rotary screw compressor: Fewer wear parts with longer service intervals

- Piston compressor: More frequent oil and part changes

Consider your holistic needs to evaluate which option fits your operations best.

When to Choose a Piston Compressor

A piston compressor supports tasks that require short bursts of high pressure without major investment. Its simple design fits smaller shops and general tool use.

A piston air compressor works well for:

- Tools requiring up to 175 to 200 PSI

- Garages and small facilities

- Lower-budget startups and maintenance teams

- Straightforward service routines

- Lower daily runtime

- Applications with many industrial air compressor types

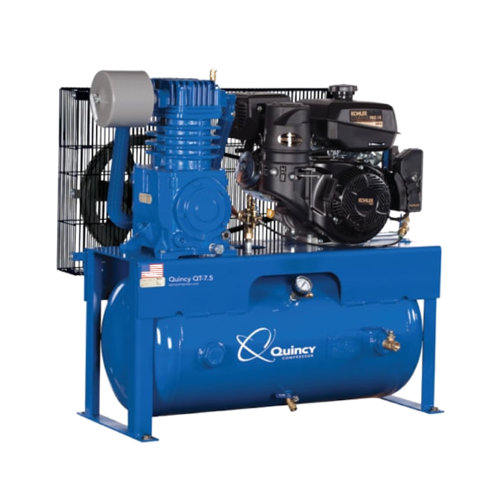

Piston Compressor Product Recommendations

At AirCompressors.com, we provide a variety of piston air compressor options from top brands like Atlas Copco and Quincy Compressor, including:

View our full lineup of piston air compressors, including stationary and portable options.

Need guidance? Our experts are here to help you select the right unit for your business – contact us today!

When to Choose a Rotary Screw Compressor

A rotary screw air compressor provides quiet operation and steady airflow throughout the day. Facilities focused on efficiency and long shifts often rely on this compressor style.

A rotary screw compressor works well for:

- Multi-hour operation

- Areas needing lower noise

- Higher airflow requirements

- Production tools needing consistent air

- Teams focused on reducing energy use

- Operations seeking long-term cost savings

Rotary Screw Compressor Recommendations

AirCompressors.com specializes in a full range of rotary screw air compressors designed to meet the demand of businesses in various industries. Our selection of rotary screw compressors also features Atlas Copco and Quincy Compressor models, known for their reliability and performance, including:

Browse all the oil-injected rotary screw compressors at AirCompressors.com.

Sizing Basics

Properly sizing your compressor helps maintain consistent performance and reduce stress on components. As you compare the different models of air compressors, make sure you follow these sizing guidelines to choose the perfect fit:

- Add the CFM of tools that may run at the same time

- Include a 25% buffer

- Match required PSI

- Choose a larger tank when pressure recovery is frequent

- Confirm filtration and drying based on air quality requirements

If you are in need of additional components for your compressor, review AirCompressors.com accessory options to help your air compressor run more efficiently.

Get Help Choosing the Right Compressor – Shop Today!

Our experts at AirCompressors.com can help you review your tools, air requirements, and daily runtime to match you with the right compressor, whether rotary screw, piston, or other models, that delivers the power, efficiency, and reliability your operation needs.

Shop our lineup of rotary screw air compressors and piston air compressors, or contact AirCompressors.com with questions to right-size your operations!