Air compressors are fundamental to modern engineering and manufacturing, powering everything from industrial machinery to everyday pneumatic tools. Their history of compressor technology dates back thousands of years—long before the invention of modern machinery. In this article, we’ll take a journey through the evolution of air compressor design, exploring how simple bellows transformed into the high-tech mechanical air compressors we rely on today. We’ll also discuss why compressed air power remains essential for industries worldwide and how air compressor energy efficiency continues to shape future innovations.

Early Uses of Compressed Air

As early as 1500 B.C., people found ways to harness compressed air for practical purposes. Ancient civilizations used bellows, simple devices that manually pumped air into fires, to reach higher temperatures for melting and forging metals. Even before bellows became widespread, individuals discovered that directing air into an enclosed space could intensify flames, improving cooking and heating efficiency. These pioneering uses of compressed air highlight just how essential and long-standing air compression has been, predating modern industrial applications by centuries.

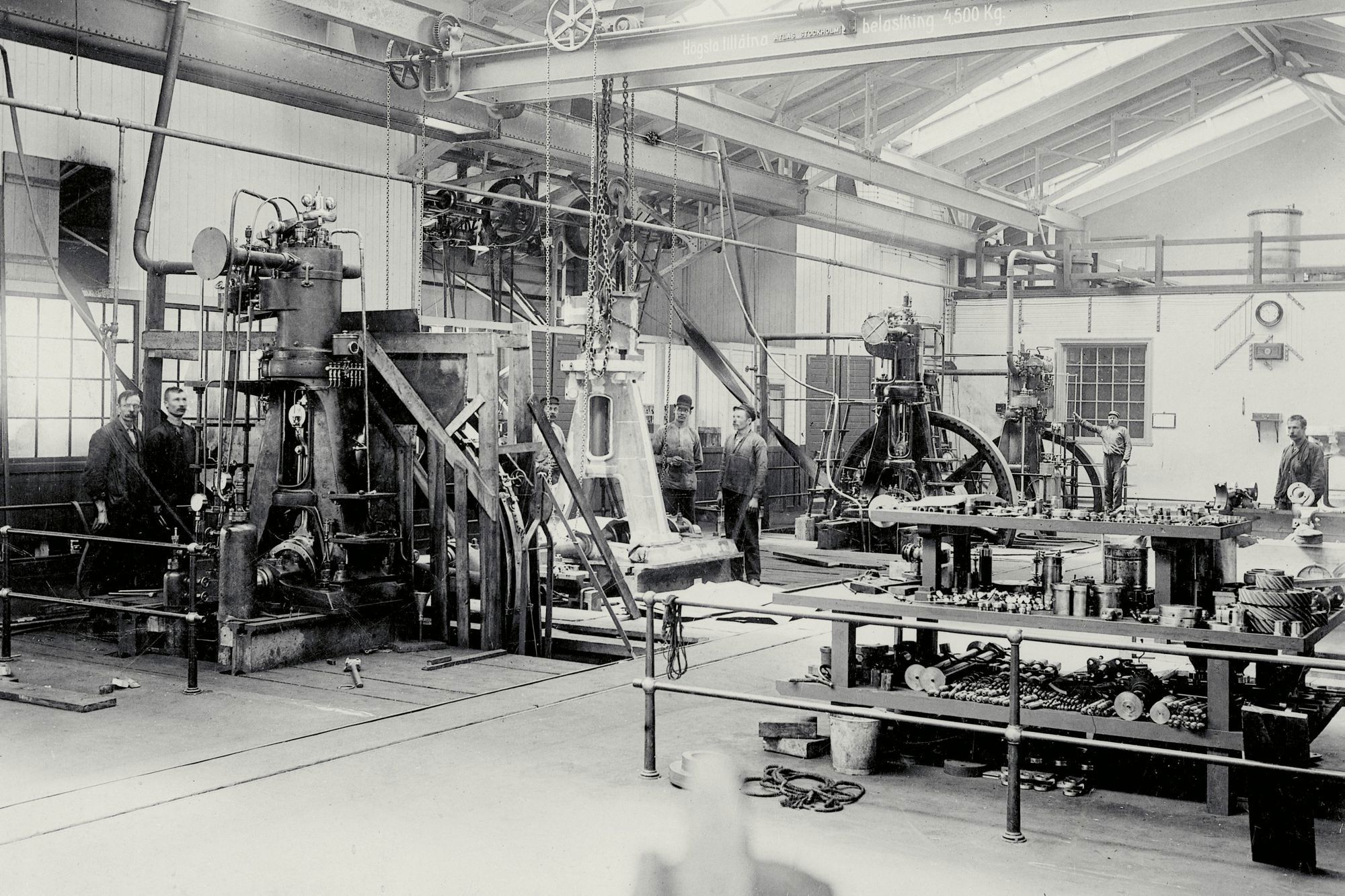

The Introduction of Mechanical Air Compressors

During the 18th and 19th centuries, the Industrial Revolution sparked major advancements in compressor history. During this period, inventors began experimenting with new ways to compress air on a larger and more consistent scale.

The First Piston Compressors

As industries grew, traditional bellows fell short of meeting demand. This led to the invention of the piston-based mechanical air compressors. These machines utilized a crankshaft, connecting rods, and cylinders to draw in air and compress it under high pressure, generating a powerful and steady flow. The reliable output of piston compressors paved the way for large-scale industrial processes, setting a new standard in efficiency and productivity.

Early Applications of Mechanical Air Compression

With the new invention of mechanical air compressors, new applications were used across many industrial processes. The consistent, high-pressure airflow of the piston compressors introduced new production methods that set the stage for rapid growth during the industrial revolution. Compressed air supported industries such as mining and manufacturing, making drilling safer and providing support for specialized tasks that required precise control like riveting and clamping.

Industrial Revolution and Growth in Air Compressor Technology

The Industrial Revolution marked a turning point in air compressor history, as new machinery and large-scale production needs pushed innovators to refine and diversify air compressor technology.

The Expansion of Compressed Air Power

- Rise of Pneumatic Tools: With advancements in compressed air technology, factories and workshops were able to implement air tools and pneumatic power for tasks like sanding, painting, and polishing, propelling the compressed air power movement forward.

- Mass Production: As assembly lines became standard, compressed air provided the consistent and controllable force needed to automate various production stages.

Advancements in Mining and Construction

- Tunneling and Infrastructure: Large-scale projects like railway tunnels relied on compressed air for jackhammers, drills, and rock-blasting equipment. These tools allowed for safer and more efficient work in challenging conditions.

- Heavy Machinery: Air-powered equipment, including concrete breakers and pneumatic hammers, became a staple on construction sites, significantly reducing labor intensity and speeding up construction processes.

The 20th Century – New Designs and Innovations

The 20th century brought a wave of new air compressor advancements, including the invention of rotary screw compressors and centrifugal (oil-free) compressors. During this time, manufacturers saw great improvements in efficiency in terms of performance and cost-effectiveness.

Read more about piston and rotary screw air compressors and their advantages and key differences.

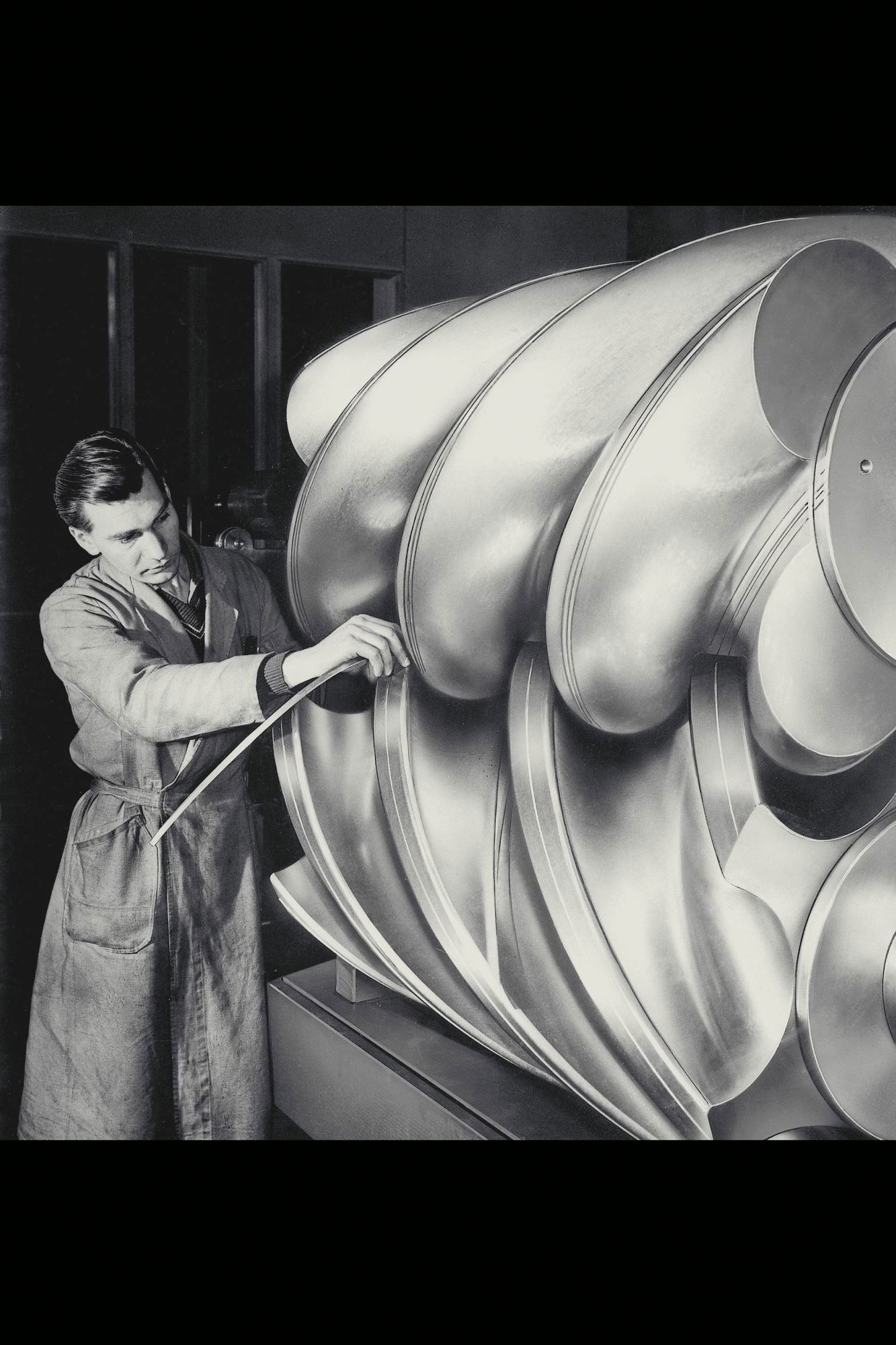

The Rise of Rotary Screw Compressors

The creation of rotary screw compressors was a significant advancement over traditional piston-based systems. By utilizing two interlocking helical rotors, these compressors were able to compress air more smoothly and efficiently than earlier designs. This new technology produced a continuous flow of air, had fewer moving parts, and required less maintenance. Additionally, rotary screw compressors operate with lower vibration and noise levels, making them well-suited for a wide range of industrial settings. Their efficiency and reliability quickly made them a popular choice for companies seeking to reduce downtime, optimize energy consumption, and scale production without sacrificing performance.

Oil-Free Compressors and Specialized Applications

Centrifugal compressors are “oil free” by design. They produce compressed air with a minimal amount of oil contamination, making it a top choice for applications needing clean air, or Class 0 oil-free air. Unlike traditional compressors that rely on oil for lubrication, oil-free models typically use specific coatings, seals, or water-based lubrication methods to ensure that no oil comes into contact with the compressed air.

Oil-free air compressors were adopted by a variety of industries due to their cleaner air output and improved safety, including in pharmaceutical tablet coating, electronic circuit board manufacturing, food processing plants and medical organizations where sterile environments were necessary.

Modern Air Compressors and Future Trends

Today’s modern air compressor offers advanced capabilities, from smart controls to sustainability features. Innovations in air compressor technology continue to push boundaries for performance and energy savings to reduce carbon footprint.

Read more about the benefits and applications of oil-free vs. oil-flooded air compressors.

Smart Air Compressors and Energy Efficiency

- IoT Integration: Many compressors now feature sensors and internet connectivity, allowing for real-time performance monitoring and predictive maintenance.

- Variable Speed Drives (VSDs): By adjusting the motor speed to match demand, VSD technology significantly boosts air compressor energy efficiency and lowers operational costs.

Sustainability and the Future of Compressed Air

- Eco-Friendly Systems: As governments and industries push for greener solutions, manufacturers focus on reducing emissions and conserving energy in compressor designs.

- Renewable Energy Integration: In some cases, compressors are powered by renewable energy sources like solar or wind, further minimizing the carbon footprint of compressed air.

The Evolution of Air Compressors – A Legacy That Drives Industry Forward

From the first bellows to today’s modern air compressor systems, the evolution of air compressors has reshaped industries and sparked innovation that has advanced how we do business. Air compressors have truly transformed the way we build, create, and power our world.

Today’s modern air compressor solutions emphasize sustainability, efficiency, and smart controls. If you’re exploring the latest compressor solutions, turn to AirCompressors.com to explore a wide selection of air compressors, for uses across all types on industries.