The piping material in your compressed air system can significantly impact its efficiency, air quality, maintenance requirements, and overall cost. Selecting the right compressed air piping is crucial to long term health for your air compressor. This guide breaks down the most common compressed air piping materials: aluminum, copper, galvanized steel, plastic/PVC, and stainless steel.

Learn about their advantages, limitations, and best use cases to help you make informed decisions for your operations.

Why Compressed Air Piping Materials Matter

Choosing the right material ensures your compressed air pipe system performs reliably and efficiently for years to come. Your equipment’s piping material plays a critical role in:

- Minimizing pressure drops and energy loss

- Preventing contamination from corrosion or debris

- Reducing downtime and repair frequency

- Supporting future system changes

- Balancing upfront and long-term costs

Five Most Common Compressed Air Piping Materials

While there are many types of air compressor piping, there are five that stand out as the most commonly utilized in current and older compressed air systems. While common, there are pros and cons to keep in mind when selecting air piping materials.

Aluminum Compressed Air Piping

Aluminum is a top choice for modern systems due to its lightweight design, corrosion-resistant air piping, and low pressure drop. It’s easy to install and ideal for modular layouts that may need future expansion.

Brands like AIRpipe offer aluminum systems with push-to-connect fittings and leak-free performance, making them a smart option for both new builds and retrofits.

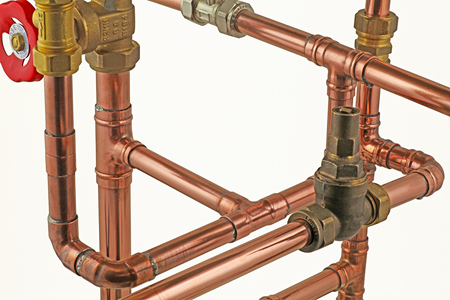

Copper Air Piping

Copper is valued for its durability and natural resistance to corrosion. It provides clean, efficient airflow and is often used in environments where air purity is critical, such as food processing and pharmaceuticals. It’s typically more expensive and requires skilled labor for installation, which can increase project costs.

Galvanized Steel Air Piping

Galvanized steel was once widely used but is now less common due to internal rusting and zinc flaking, which can contaminate air systems. It’s heavy, harder to install, and prone to pressure drops.

While still found in older systems, it’s generally not recommended for new installations.

Plastic and PVC Compressed Air Piping

Plastic and PVC piping are inexpensive and easy to install but come with significant safety concerns. They are not rated for compressed air in most industrial settings and can burst under pressure.

These materials may be suitable for temporary or low-pressure setups but are typically non-compliant with safety codes.

Stainless Steel Air Piping

Stainless steel is ideal for harsh environments with high pressure, temperature, or chemical exposure. It’s extremely durable and corrosion-resistant but comes with high material and labor costs.

Specialized applications like chemical plants or marine facilities are best suited to stainless steel.

Summary Table: Quick Comparison of Piping Materials

| Material | Cost | Durability | Installation Ease | Pressure Resistance | Ideal Applications |

| Aluminum | $$ | High | Easy | High | Industrial, commercial |

| Copper | $$$ | High | Moderate | High | Clean manufacturing, pharma |

| Galvanized Steel | $$ | Low | Difficult | Moderate | Legacy systems only |

| Plastic/PVC | $ | Low | Easy | Low | Temporary, non-critical |

| Stainless Steel | $$$$ | Very High | Difficult | Very High | Harsh, corrosive, or extreme settings |

How System Design Factors into Material Choice

While material selection is critical, system layout is another component to keep in mind when choosing your piping materials.

- Loop systems benefit from low-pressure-drop materials like aluminum.

- Modular systems require piping that's easy to reconfigure—like AIRpipe's push-to-connect aluminum systems.

- Air quality requirements may dictate corrosion-resistant materials like copper or stainless steel.

Learn about choosing the best system layout for your facility in our Resource Center.

Energy Efficiency and ROI: The Hidden Impact of Piping Choices

Leaks and pressure drops can significantly increase energy costs. Choosing the right piping material, especially aluminum or stainless steel, can:

- Reduce air leaks

- Lower compressor workload

- Improve system efficiency

- Deliver long-term energy savings

AirCompressors.com is proud to offer AIRpipe aluminum piping systems, engineered for leak-free performance and minimal pressure loss. AIRpipe USA products help facilities reduce energy waste and improve ROI.

Not sure where to start? Reach out to our dedicated team for expert advice.

Need Help Choosing? Talk to Our Piping Experts

Selecting the right compressed air piping material can be complex, but you don’t have to do it alone. Our team at AirCompressors.com is here to help you evaluate your system requirements and compare material options.

Contact our piping experts to see how AIRpipe products can reduce air leaks and improve system efficiency.